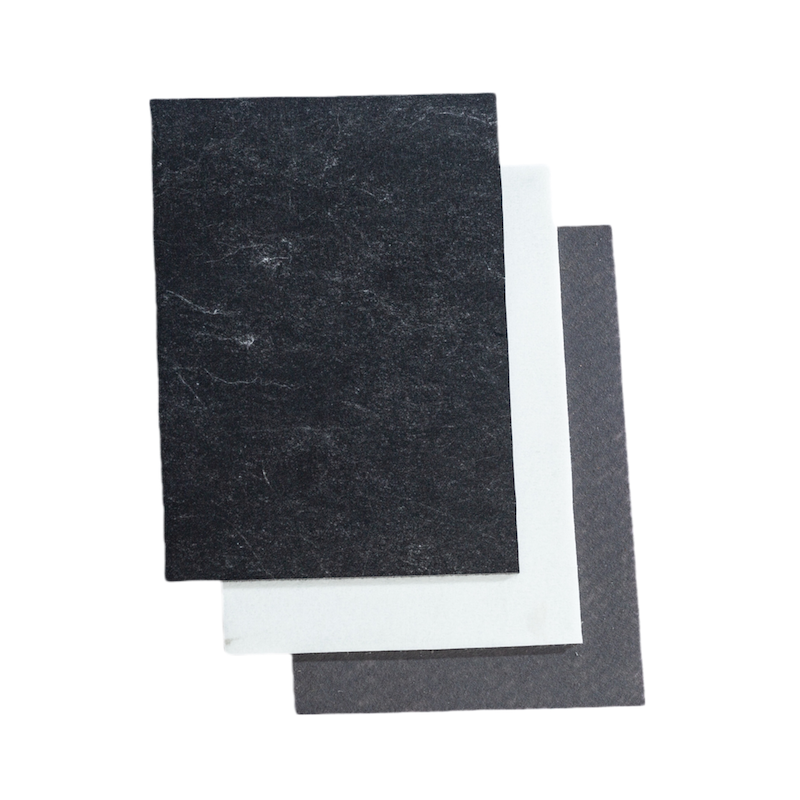

GMT(Glass Mat Reinforced Thermoplastic)

GMT (Glass Mat Reinforced Thermoplastic) Due to its excellent strength, stiffness and impact resistance, GMT is mainly used as a “semi-structural component” and is an ideal material for replacing metal to achieve lightweighting.

描述

01 Our GMT Sheet Material Overview

1. Definition and Composition

Definition of GMT Materials

GMT (Glass Mat Thermoplastics) is a thermoplastic composite material consisting of thermoplastic resin and glass fiber.

Main Ingredient Analysis

GMT materials are mainly composed of polypropylene (PP) or polyamide (PA) as the matrix resin and randomly distributed glass fiber mats.

Performance Characteristics

GMT materials have good mechanical properties, heat resistance, and chemical resistance, and are easy to process and shape, and are widely used in the automotive industry.

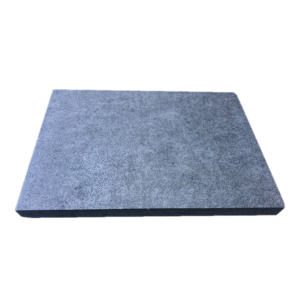

2. GMT Sheet Specification & Performance

| Material (g/m²) | Tensile Strength (MPa) | Flexural Modulus (MPa) | Relative Density |

|---|---|---|---|

| 700 | 7.8 | 860 | 0.338 |

| 800 | 9 | 1215 | 0.378 |

| 900 | 9.5 | 1450 | 0.418 |

| 1000 | 15 | 1800 | 0.458 |

| 1200 | 18.5 | 2000 | 0.504 |

| 1400 | 27.5 | 2600 | 0.603 |

| 1600 | 40 | 3400 | 0.711 |

| 2000 | 47 | 4800 | 0.848 |

| 3000 | 53 | 6300 | 0.961 |

3. GMT Sheet Performance

| GMT Sheet (g/m²) | Sheet Thickness (mm) | Thickness after heating (mm) | Thickness range for Molding (mm) |

|---|---|---|---|

| 700 | 2.5-2.8 | 4.5-5 | 1.5-3.5 |

| 800 | 2.5-3.0 | 4.7-5.2 | 1.5-3.5 |

| 900 | 3.0-3.5 | 5.3-5.8 | 2-4 |

| 1000 | 3.0-4.0 | 6-6.5 | 2-4 |

| 1200 | 3.0-4.0 | 7.2-7.7 | 2-4.5 |

| 1400 | 3.0-5.0 | 8.5-9 | 2-5 |

| 1600 | 3.0-5.0 | 9.5-10 | 2-6 |

| 1800 | 3.5-6.0 | 10.5-11 | 3-6 |

| 2000 | 3.5-6.0 | 11-12.5 | 3-6 |

| 3000 | 4.0-8.0 | 12.5-13.5 | 3-10 |

02 The Advantages of GMT Sheet Material

Lightweight and High-Strength Characteristics

- Low Density, High Specific Strength: GMT materials have a low density and high specific strength, leading to their widespread application in the aerospace industry.

- Excellent Impact Resistance: GMT materials can absorb a significant amount of energy upon impact and are resistant to fracture, making them suitable for components such as automotive bumpers.

- Good Fatigue Resistance: GMT materials exhibit strong fatigue resistance, capable of withstanding long-term repeated stress without failure, which is ideal for manufacturing structural parts for long-term use.

- Stable Coefficient of Thermal Expansion: The coefficient of thermal expansion for GMT materials is low and stable, ensuring dimensional stability under temperature changes and making them suitable for precision instrument casings.

Comprehensive Performance Comparison and Analysis of GMT with Metal Materials: Steel and Aluminum

| Performance Indicator | GMT | Steel | Aluminum |

|---|---|---|---|

| Density (g/cm³) | 1.01-1.19 | 7.8 | 2.7 |

| Specific Strength | High | Low | Medium |

| Corrosion Resistance | Excellent | Poor (requires surface treatment) | Medium (prone to oxidation) |

| Impact Energy Absorption | Extremely High | Low | Medium |

| Production Energy Consumption | Low | High | Medium |

Comprehensive Performance Comparison and Analysis of GMT with Thermoplastic Composites: LFT-G and LFT-D

| Performance Indicator | GMT | LFT-G | LFT-D |

|---|---|---|---|

| Fiber Length | Continuous/Long Fiber (>50mm) | Medium (1-5mm) | Medium (5-20mm) |

| Impact Strength | Extremely High | Medium | Medium-High |

| Production Flexibility | Medium | High | Extremely High |

| Initial Investment | Medium | Low | High |

| Suitable Batch Size | Large Volume | Small to Medium Volume | Small to Medium Volume |

Comprehensive Performance Comparison and Analysis of GMT with Thermosetting Material: SMC

| Performance Indicator | GMT | SMC |

|---|---|---|

| Production Process Efficiency (min) | 0.5-1 | ≥3-5 |

| Impact Toughness | Ultra-High Impact Performance | |

| Environmental Characteristics | Can be remelted and recycled multiple times |

03 Application of GMT Sheets

-

Fender

-

Truck roof

Truck roof

- Bus door panel

-

Car roof

Car roof Car roof -

Wheel cover

-

Car coat rack

-

Tonneau cover support frame