Application and Research of LWRT on Automotive Exterior Parts(1)

Abstract: This article takes a certain vehicle model as an empirical case to study the innovative application of lightweight reinforced thermoplastic (LWRT) composite material in automotive exterior components. Through multi-layer composite structure design and compression molding process optimization, LWRT achieves breakthroughs in performance, including lightweight, high rigidity, wide-frequency sound absorption, and resistance to extreme environments. Compared with traditional PP-T20 materials, it has considerable advantages in weight reduction, cost reduction, and vehicle NVH performance optimization. This research provides a design specification for the exterior design of new energy vehicles that balances performance improvement and economic feasibility.

Keywords: LWRT; Automotive Lightweight; Molding Process; NVH Performance; Thermoplastic Composite Material

0 Introduction

As the global automotive industry accelerates its transformation towards electrification, intelligence, and green, low-carbon development, lightweighting has become one of the key technologies for automotive innovation. According to national energy conservation and environmental protection requirements, for every 10% reduction in the weight of a new energy vehicle, its driving range can be increased by 5%-7%. In this context, the research and application of new composite materials have become key to breaking through the bottleneck of lightweight technology.

LWRT (Low Weight Reinforced Thermoplastics/lightweight reinforced thermoplastic material) has significant lightweight properties due to its characteristics (lower density, lighter than traditional materials), environmental performance (odorless, low VOC, non-hazardous substances can be left in the trunk for a long time, recyclable), and better mechanical properties (has a certain degree of high modulus, good impact toughness and pull-out strength), acoustic properties (excellent sound absorption and sound insulation performance), flame retardancy (combustion speed is less than 30 mm/min), and molding performance (the thickness can be four times thicker than the original sheet after heating, and can be dimensionally stable after cooling). This article takes the application of LWRT on the exterior trim of a certain vehicle model as an example to explore its system solutions, verify its design feasibility in practice, and summarize its comprehensive advantages in lightweighting, technology, and innovative applications. The aim is to demonstrate the comprehensive advantages of its lightweighting and functional enhancement.

The mold development cycle can be shortened from 75 days to 35 days, providing technical assurance for rapid response to market demand. LWRT provides a systematic solution for automotive exterior lightweighting with its unique structural design and performance advantages. This article focuses on the lightweighting technical solutions for automotive exterior parts, and through the comparison of material performance metrics and systematic analysis of technical applications, it analyzes the theoretical basis for its application case by case.

1 Analysis of LWRT Material Characteristics and Advantages

Taking a certain vehicle model as an example, exterior parts such as the front engine cover, wheelhouse liner, and underbody shield are all made of LWRT material, which meets the new demands of new energy vehicles for airflow management, NVH optimization, and cost control. Through multi-layer composite structure and process innovation, the actual weight reduction of parts is 30%-50%, and it can also shorten the development cycle from 75 days to 35 days, providing a solution that balances performance and cost. Let’s analyze its performance advantages and theoretical basis using the case of an underbody shield.

1.1 Material Composition and Structural Characteristics: The Technical Basis of Functional Layering

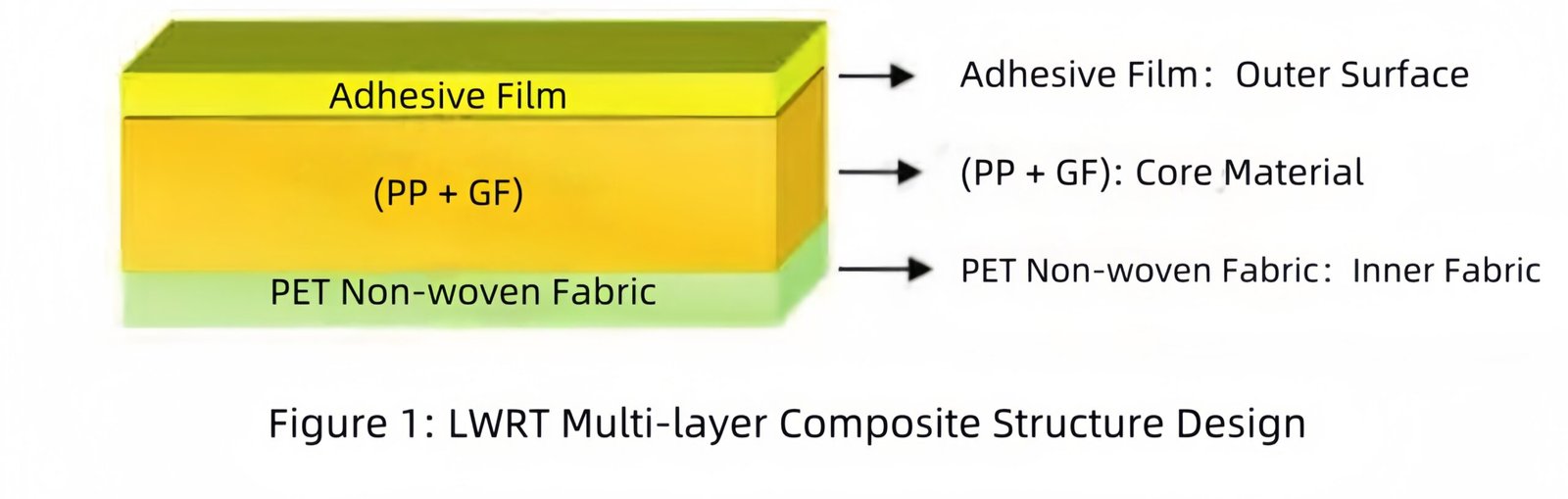

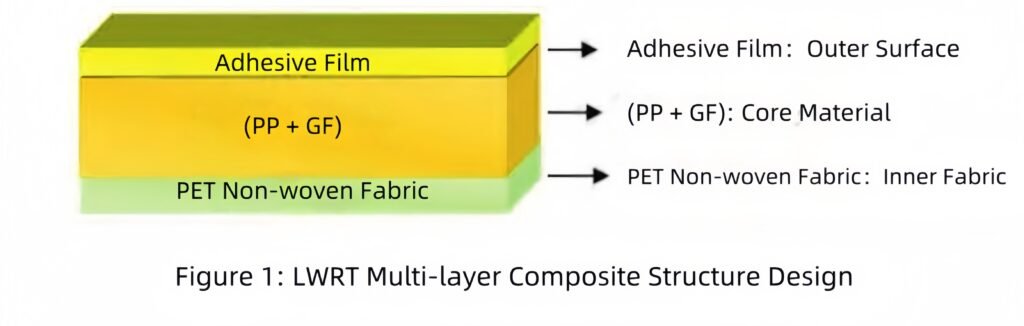

The core competitiveness of LWRT lies in its multi-layer composite structure design. The synergy of different layers realizes the lightweighting of parts and directly defines its advantages in acoustics, mechanics, and durability. It is mainly divided into three layers (Figure 1).

(1) Sound absorption and noise reduction layer. The PET non-woven fabric and hot-melt fiber interweave to form a porous sound-absorbing structure, with a porosity as high as 30% ~ 50%, endowing the material with excellent sound absorption performance. It can achieve a sound absorption coefficient α > 1.0 (can reach 0.933) for a 6.3 kHz sound source. The specific performance requirements in terms of vehicle NVH are as follows.

(2) Rigidity layer. The inner matrix (PP) is a composite of PP base material and long glass fibers (GF content 50%), which undergoes further enhancement through a hot-pressing process. The high-temperature activated glass fibers interweave to form a three-dimensional network structure, and its excellent flexural modulus can exceed 12,000 MPa.

(3) Impact and scratch resistance layer. The surface layer is a PP-based adhesive film or felt, which can effectively resist chipping from flying stones and corrosion. The impact resistance is > 5 J, which can effectively block damage from flying stones.

1.2 Key Performance Advantages: From Theory to Measured Breakthroughs

Based on the above discussion of the material and structural advantages of LWRT itself, the following will discuss how it achieves functional breakthroughs.

(1) Lightweight. Lightweighting is not a simple “subtraction,” but requires a dynamic balance between density and strength to meet the dual demands of both. In terms of structural design, the LWRT is divided into functional layers. The thickness is allocated as: sound-absorbing layer 0.5 mm, rigidity layer 1.5 mm, and impact-resistant layer 0.5 mm. By partitioning functions to reduce redundant material volume, while ensuring mechanical performance, the material is compressed by 30% compared to traditional PP-T20. The PP matrix with a density of 0.90 g/cm³ is used as the base material, combined with the lightweight PET non-woven fabric with a density of 1.38 g/cm³. By adjusting the porosity, the overall density is reduced to 0.56 g/cm³.

(2) Acoustic Performance. LWRT shifts from micro-pore regulation to a macroscopic acoustic gradient structure to improve its acoustic performance. Micro-level pore design: The LWRT sound-absorbing layer uses a PET non-woven fabric with a fiber fineness of 50 ~ 500 μm in a gradient network. The pores inside the material are distributed in a gradient, which, through the “reflection-scattering-viscous damping” mechanism within the pores, covers a wide noise frequency range from 50 Hz ~ 6.3 kHz. Next, from the macroscopic level, the surface anti-resonance design: Because the back of its rigidity layer is a dense PP substrate, with a surface roughness Ra of less than 1.6 μm, combined with the porous multi-layer structure on top, it forms an impedance transition boundary, greatly reducing the reflection of sound waves and improving the sound absorption efficiency in the mid-to-low frequency range of 200 ~ 1,000 Hz.

(3) Environmental Resistance. The core of this design lies in predicting failure modes under extreme working conditions such as high-temperature environments and severe impact environments, and achieving resistance to irreversible damage through proactive intervention in materials and processes. In terms of thermal stability design, antioxidants and cross-linking agents are added to the PP matrix, increasing its glass transition temperature (Tg) from 80°C to 110°C, delaying high-temperature softening and enhancing the matrix’s heat resistance. In addition, the PET non-woven fabric and the PP matrix are chemically grafted to enhance interlayer adhesion, avoiding interface delamination caused by differences in thermal expansion coefficients, and increasing interface aging resistance. In terms of impact toughness design, the LWRT material’s impact-resistant layer adopts a gradient densification structure, that is, the surface density decreases in a gradient from 1.2 g/cm³ at the surface to 0.8 g/cm³ in the interior. Through a progressive energy dissipation mechanism (elastic deformation – plastic yielding – fiber fracture), the impact energy from flying stones is dispersed over a larger volume, enhancing impact resistance.