Application And Research Of LWRT On Automotive Exterior Parts(2)

Comparative Analysis with Traditional Materials: Comprehensive Leadership in All Aspects

Compared to traditional PP-T20 material, the advantages of LWRT are manifested in the following aspects.

(1) In the field of lightweighting, the density of LWRT is only 0.56 g/cm³, which is 46.7% lower than the 1.05 g/cm³ of PP-T20. This physical characteristic directly translates into a significant weight reduction effect (Table 1). Taking the underbody shield of a certain vehicle model as an example, the weight of a single part was reduced from 12.74 kg to 6.70 kg, a weight reduction ratio of 47.3%. This lightweighting is not achieved at the cost of structural strength; the flexural modulus of LWRT is 9% higher than that of PP-T20, and its specific stiffness (rigidity per unit mass) is even doubled, supporting the stability of thin-walled designs under high-speed wind loads.

Table 1 Comparison of LWRT and PP-20 in terms of lightweighting

| Indicator | LWRT | PP-T20 | Advantage Analysis |

| Density (g/cm³) | 0.56 | 1.05 | Density reduced by 46.7% |

| Single Part Weight Reduction Ratio | ≥50% (Taking the underbody shield as an example) | ≤15% (Injection molding optimization limit) | Weight reduction efficiency increased by more than 3 times |

(2) The breakthrough in acoustic performance is also evident. The LWRT sound absorption layer, through its 50-500 μm gradient pore network, achieves a sound absorption coefficient of 0.93 in the 6.3 kHz high-frequency band, an improvement of 43% over PP-T20. In actual vehicle NVH tests, under a constant speed of 60 km/h, the in-cabin noise was reduced by 3.3 dB, and the subjective quietness rating improved by 20% (Table 2).

(3) In terms of environmental resistance, LWRT demonstrates strong adaptability to extreme working conditions. In a 125°C high-temperature environment for 400 consecutive hours, the material showed no deformation or performance degradation, whereas PP-T20 began to experience edge warping after 168 hours at 85°C. In low-temperature impact tests, LWRT maintained a 100% pass rate with no cracking at -40°C, a significant improvement over PP-T20’s 70%. In the stone chip impact test, the dent depth caused by a 9.5 mm stone chip was only 2.0 mm, which is half of the 4.0 mm depth on the traditional material (Table 3).

Table 2 Comparison of LWRT and PP-20 in terms of acoustic performance

| Indicator | LWRT | PP-T20 | Advantage Analysis |

| Sound Absorption Coefficient (6.3 kHz) | 0.93 | 0.65 | High-frequency sound absorption rate increased by 43% |

| Sound Insulation (63 Hz-4kHz avg) | 32dB | 26 dB | Overall vehicle NVH performance optimized by 23% |

Table 3 Comparison of LWRT and PP-20 in terms of environmental resistance performance

| Indicator | LWRT | PP-T20 | Advantage Analysis |

| High-Temperature Aging Conditions | 120 °C / 400 h No failure | 85 °C / 168 h Edge warping | Heat resistance reliability extended by 2.4 times |

| Low-Temperature Impact Pass Rate (-40 ℃) | 100% (No cracking) | 70% (Local cracking) | Cold resistance reliability improved by 42.9% |

| Stone Chip Impact Dent Depth (mm) | ≤2.0 (9.5 mm stone chip) | ≥4.0 | Damage resistance capability increased by 100% |

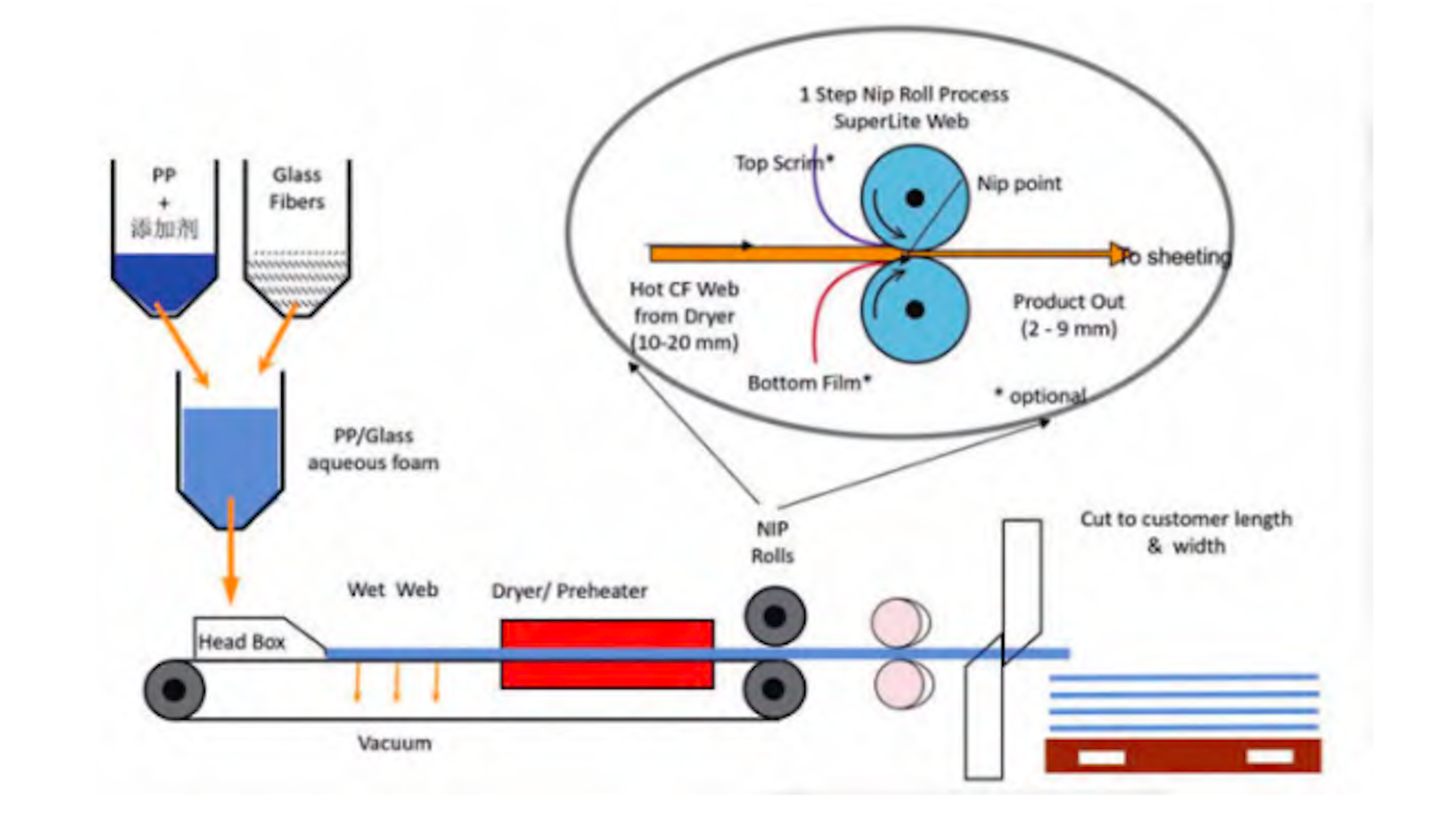

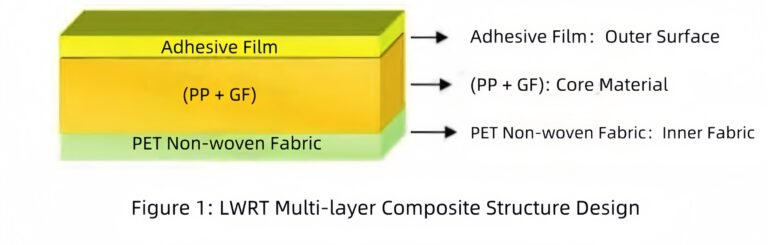

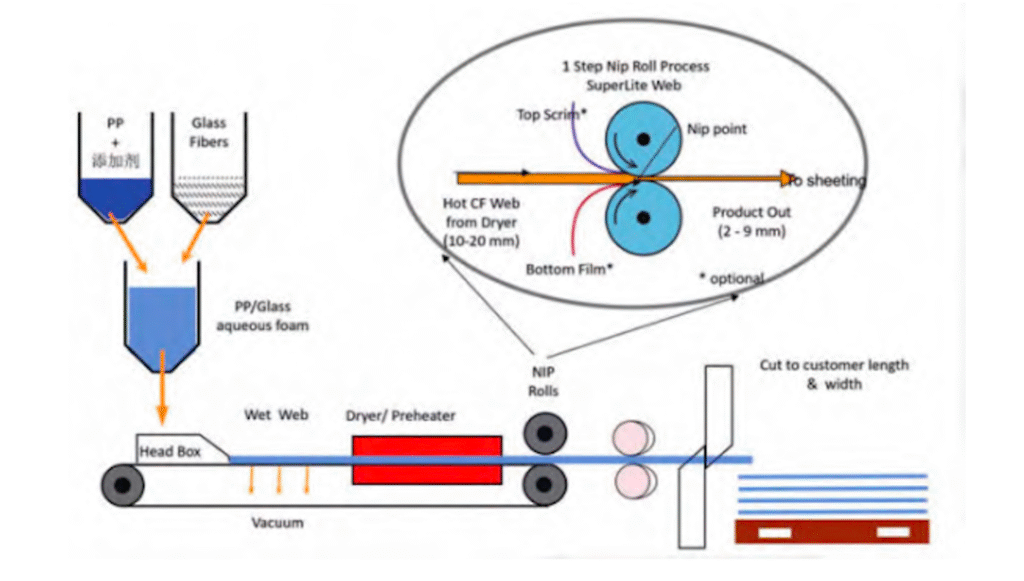

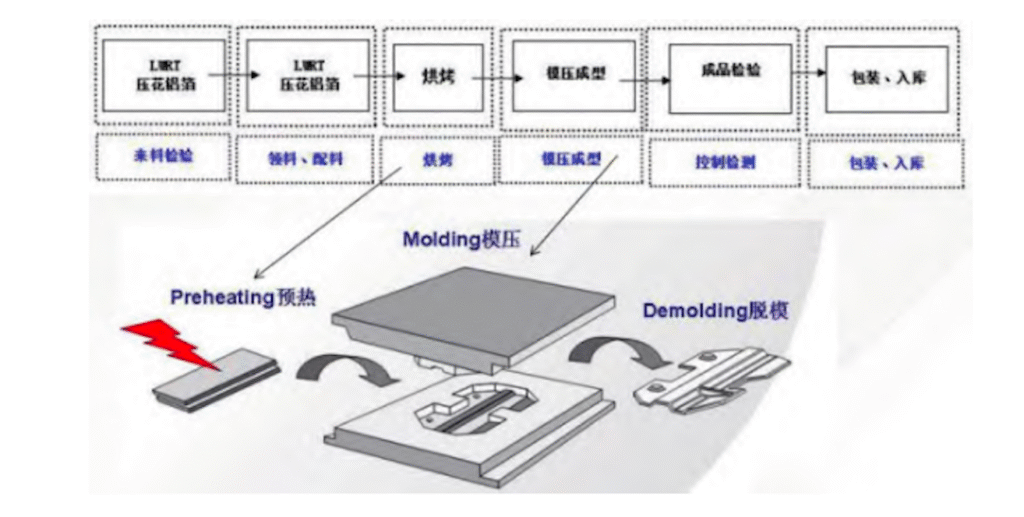

In addition to the comparison of key performance aspects, it is also necessary to compare their development processes (Figure 4, Figure 5). Adopting a compression molding process, its rapid curing characteristic (180°C / 3 min) not only shortens the production cycle by 50%, but its flexible mold-changing capability also supports the co-line production of multiple vehicle models. During the hot pressing process, temperature fluctuations must be strictly controlled within ±2°C to avoid localized weakening caused by uneven fiber distribution; the pressure gradient is maintained stable through a closed-loop feedback from the hydraulic system, ensuring the uniformity of the porous structure. Achieving a balance of temperature, pressure, and time, project data from this vehicle model shows that the material utilization rate of the compression molding process reaches 85%, a 10% increase over the injection molding process. The recycling rate for scrap and off-cuts is as high as 95%, demonstrating significant environmental benefits.

The innovation in the joining technology between LWRT material and its other parts is also key. The composite solution of laser welding and structural adhesive not only solves the interface compatibility issue between LWRT and the traditional metal car body but also avoids the weight redundancy of purely mechanical fasteners. Laser welding forms a 0.1 mm-level micro-weld seam at the installation points of the underbody shield, with its joint strength being 18% higher than traditional spot welding; while the application of epoxy structural adhesive not only fills the microscopic gaps between components, its viscoelastic properties further optimize NVH performance by 3 dB. The economic benefits of this hybrid joining strategy are also significant. A single vehicle saves 12 yuan in bolt costs. Based on an annual production of 100,000 units, the annual cost reduction reaches 1.2 million yuan.

[Figure 4 LWRT Material Forming Process. The diagram shows raw materials like PP, glass fibers, and additives being mixed, then processed through rollers to create a sheet product, which is then cut to customer length and width.]

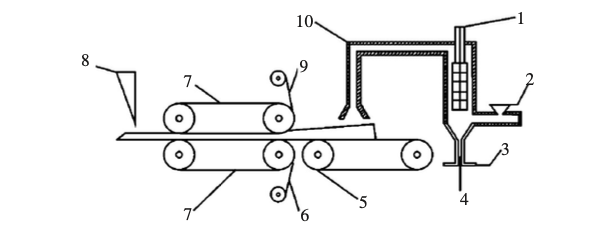

[ Figure 5 Component Production Process. The flowchart and diagram show the steps: raw material inspection, feeding, preheating, molding (compression molding), demolding, product inspection, and finally packaging and warehousing.]

In summary, LWRT not only redefines the technical standards for exterior trim materials but also opens up an industrialization path that balances performance enhancement with commercial viability.