Electrical Aluminum (Copper) Foil Shielding Insulating Paper: The Key to Enhancing Electrical Equipment Safety and Reliability

Product Overview

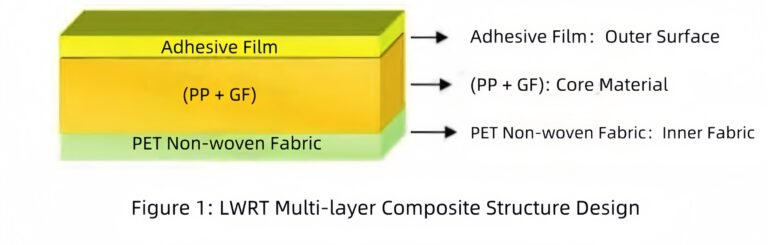

Electrical Aluminum (Copper) Foil Shielding Insulating Paper is a high-performance composite insulation material specifically designed for modern electrical equipment. It is manufactured by laminating high-density electrical insulating paper with high-purity aluminum or copper foil using a special bonding process. This innovative shielding material is primarily used in critical electrical apparatus such as transformers, mutual inductors, and reactors, where it functions as a ground screen, electrostatic shielding layer, and coil conductive layer. Its main purpose is to optimize the electromagnetic field distribution within the equipment, significantly reduce partial discharge, and thereby enhance insulation performance, decrease losses, and ultimately improve the overall safety and reliability of operation.

Core Advantages and Working Principle

In high-voltage equipment like transformers, uneven electric field distribution and transient over-voltages are primary causes of premature aging and failure of the insulation system. Electrical Aluminum (Copper) Foil Shielding Insulating Paper effectively addresses these issues through its unique structure:

- Improved Electromagnetic Field Distribution & Electrostatic Shielding: The aluminum or copper foil acts as a conductive shield, effectively reducing the capacitive coupling between windings. This shield intercepts and diverts high-frequency noise and transient voltage spikes, preventing them from being transmitted between the primary and secondary windings.This protects sensitive electronic components and improves overall system reliability. This electrostatic shielding action ensures a more uniform electric field distribution, preventing localized high-stress points from damaging the insulation material.

- Reduction of Partial Discharge (PD): Partial discharge is a key factor leading to the degradation and eventual failure of insulation materials. By optimizing the electric field distribution and eliminating potential floating electrodes, the shielding insulating paper significantly reduces the likelihood of partial discharge occurring. This helps to extend the service life of the insulation system, ensuring the long-term, stable operation of transformers and other equipment.

- Reinforced Insulation and Loss Reduction: The base material, a high-density electrical insulating paper, possesses excellent dielectric strength and mechanical toughness. When combined with the high-purity conductive metal foil, it not only provides a reliable insulating barrier for the windings but its shielding effect also helps to reduce eddy current losses, thereby increasing the operational efficiency of the equipment.

Key Material Properties

The superior performance of this product stems from the strict selection of its base materials and the precision of the lamination process.

1. Base Paper Performance Requirements

As the main component for insulation and structural support, the properties of the base paper are critical.

- Thickness and Compactness: A thickness of 0.13 mm and a high compactness of 1.05-1.20 g/cm³ ensure the material has good mechanical strength and resistance to electrical breakdown.

- High Purity and Chemical Stability: An extremely low ash content (≤1.0%) and strictly controlled conductivity and pH levels of its water extract guarantee the chemical purity of the paper. This is crucial for preventing chemical reactions within the transformer oil and maintaining the oil’s insulating properties.

2. Aluminum (Copper) Foil Performance Requirements

As the conductive shielding layer, the purity and uniformity of the metal foil directly impact the shielding effectiveness.

- Thickness and Purity: The use of a 0.018 mm thick metal foil with a purity of 99% ensures excellent conductivity and consistent shielding performance.

3. Finished Shielding Insulating Paper Performance Requirements

The final product combines the advantages of both the paper and the foil to achieve superior performance standards.

- Mechanical Properties: A longitudinal tensile strength of ≥160 N/10mm and an elongation at rupture of ≥2.0% allow it to withstand the mechanical stresses of the winding process without breaking.

- Electrical Strength: The material exhibits very high electrical strength in both air and transformer oil, which is a core indicator for ensuring safe operation under various conditions. Its excellent performance in oil is particularly effective at preventing insulation breakdown.

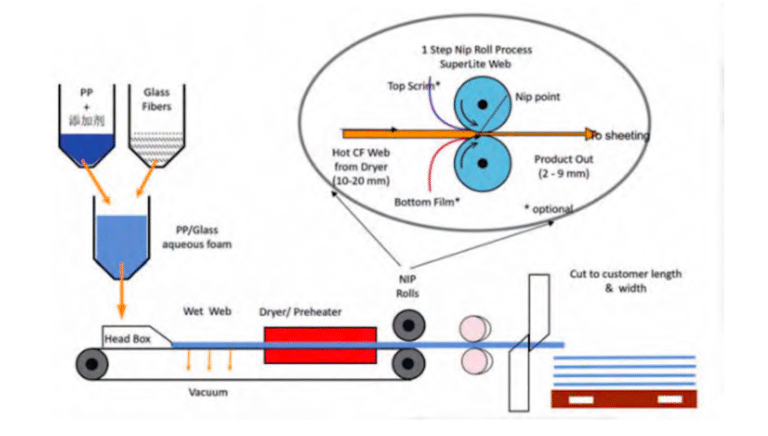

Brief Introduction to the Manufacturing Process

The product is created using a special bonding process that ensures a firm and uniform bond between the high-density insulating paper and the metal foil. Common lamination methods include dry, wet, and thermosetting processes. This procedure involves precise control over the application of adhesive, drying, and pressing stages to guarantee the overall flatness and performance consistency of the composite material, preventing defects like delamination or wrinkling that could compromise its application in electrical equipment.

Conclusion

With its significant advantages in improving electromagnetic fields, suppressing partial discharge, and enhancing insulation, Electrical Aluminum (Copper) Foil Shielding Insulating Paper has become a key material in the manufacturing of high-quality, long-life transformers, mutual inductors, and reactors. Its outstanding comprehensive properties provide a solid guarantee for the safe and reliable operation of power systems.

◎ Recommended width:

1440mm±15mm、785mm±15mm; it can be slit into bobbins or according to customers’ requirements.

◎ Storage

The product should be sealed with moisture-proof paper and plastic film.The produt should be stored in dry,clean place 300mm above the ground.

| No. | Property | Unit | Requirements | |

| 1 | Base paper performance requirements | |||

| 1.1 | Thickness | mm | 0.13±0.01 | |

| 1.2 | Compactness | g/cm³ | 1.05~1.20 | |

| 1.3 | Ash content | % | ≤1.0 | |

| 1.4 | Conductivity of water extract | mS/m | ≤6.0 | |

| 1.5 | PH value of water extract | — | 6.0~9.0 | |

| 2 | Aluminum foil (copper foil) performance requirements | |||

| 2.1 | Thickness | mm | 0.018±0.001 | |

| 2.2 | Purity | % | 99 | |

| 3 | Aluminum foil (copper foil) shielding insulating paper performance requirements | |||

| 3.1 | Thickness | mm | 0.15±0.02 | |

| 3.2 | Tensile strength MD | N/10mm | ≥160 | |

| 3.3 | Elongation at rupture MD | % | ≥2.0 | |

| 3.4 | Electrical strength | In air | kV/mm | ≥55.0 |

| In oil | ≥6.0 | |||

-3-768x491.jpg)