Application And Research Of LWRT On Automotive Exterior Parts(3)

2 Analysis of Practical Application Results of Exterior Parts

As the demand for lightweighting, driving range, and ride comfort in the new energy vehicle market becomes increasingly urgent, LWRT, as a core technology breakthrough for a certain vehicle model, has been applied to the development of exterior components.

2.1 Application Results

(1) Lightweighting. The underbody shield uses LWRT to replace traditional PP-T20 material, reducing the single part weight from 12.74 kg to 6.7 kg, and the thickness from 3.0 mm to 2.5 mm. The drag coefficient value was reduced by 24 counts. The wheelhouse liner, while improving its sound absorption performance by 40%, had its weight reduced from 4.76 kg to 3.50 kg, a reduction of 30%. The above measures resulted in a cumulative weight reduction of 7.26 kg for this vehicle model during its development process. Combined with aerodynamic optimizations, the WLTP driving range was increased by 7.6 km (for the PHEV model) to 9.6 km (for the EV model).

(2) Performance Enhancement. In terms of NVH optimization, the LWRT sound absorption layer’s sound absorption coefficient reached 0.93 in the 6.3 kHz high-frequency band, a 43% improvement over PP-T20’s 0.65. Through road tests to verify the actual vehicle noise reduction effect, at a constant speed of 60 km/h, the in-cabin noise was reduced from 68.5 dB to 65.2 dB, with the noise reduction in the wheelhouse area reaching 5 dB. In terms of environmental resistance, it showed no deformation after continuous heating at 125°C for 400 h, maintained a pass rate of > 95% in a -40°C environment, and exhibited high low-temperature performance; in a steel ball drop test from a height of 1 m, there was no cracking. In the stone chip impact test, the dent depth from a 9.5 mm gravel was ≤ 2.0 mm, which was less than the ≥ 4.0 mm of PP-T20.

(3) Economic Benefits. The comprehensive cost of using LWRT is 43.2% lower than that of PP-T20. The tooling cost for the compression molding process is reduced to 1/8 to 1/10 of injection molding, and the mold development cycle is shortened from 70 days to 35 days. For this vehicle model project, the total investment was reduced by 205 million yuan, combined with the extended driving range (7.6 km/vehicle), the total life cycle value was fully demonstrated (Table 4).

Table 4: Comparison of Economic Benefits between LWRT and PP-20

| Indicator | LWRT | PP-T20 | Advantage Analysis |

| Mold Cost (10,000 Yuan/set) | 10 (Compression Molding) | 80 (Injection Molding) | Mold investment reduced by 87.5% |

| Comprehensive Cost per Piece (Yuan) | 103.92 | 72.56 | Significant life-cycle benefits |

| Development Cycle (Days) | 35 | 70 | Production efficiency increased by 100% |

Note: The unit of currency is Chinese Yuan (RMB).

2.2 Technical Challenges and Solutions

Through the first application of LWRT in the development of exterior parts of a vehicle model, the difficulties in simultaneously achieving lightweighting, NVH, and environmental performance, which are hard to balance with traditional materials, were overcome. Through the innovation of tooling and processes, the development cycle of a single component was shortened from its original state.

(1) Precision Control in Mass Production. The preheating and draping of the blank, and the precision control of pressure during compression molding, require precise control of fiber distribution (50%±2%) and porosity uniformity. For this vehicle model, a high-precision online monitoring system with an error of ≤ 1 mm was added to the exterior component assembly line, combined with infrared thermal imaging to monitor the die temperature (180±2℃), to ensure consistent fiber orientation, and achieve a dimensional stability of ≥90% after DOE verification, reducing the scrap rate and increasing the raw material utilization rate to ≥85%.

(2) Cost Pressure. LWRT raw materials have a high initial cost, posing a certain cost pressure. A precise ratio of fiber/PP base material was first determined to achieve a combination of lightweighting and regeneration; and under the premise of ensuring performance, the raw material cost was reduced by 15%; furthermore, a reusable tooling strategy was adopted, which, combined with the flexible mold changing design of the model, could support the co-line production of parts for different models.

(3) Adjustability in Vehicle Integration. The dimensional stability is difficult to control in the early stage of tooling. During the mule car testing phase, there were instances where the underbody shield could not be assembled, and there was a risk of the CAE simulation being inaccurate. Through the optimization of the fiber layup structure, the thermal deformation was reduced from 3.0 mm to 2.5 mm, and the tensile strength of the part was increased by 22% by designing adjustable structures at the installation points of the underbody shield; simultaneously, for the scratch risk of the front engine cover, the scratch resistance was improved by 18%.

3 Social Benefits and Future Challenges

3.1 Social Benefits

(1) Economic Benefits. The application of LWRT material in this vehicle model balanced the three aspects of performance, cost, and market. The project’s total investment return on investment (ROI) period was shortened by 18 months. An estimated 6.15 million yuan in tooling costs was saved for the project. For the vehicle, after achieving a weight reduction of 7.26 kg and a WLTP range increase of 7.6 km, the total life cycle cost is reduced by 1,200 yuan per vehicle, and after 8 years, the total fleet can save 9.6 billion yuan; it reduces tire wear and improves the reliability of suspension and other components, with an estimated annual maintenance cost saving of about 300 yuan. The vehicle model is labeled as “Lightweight + Long Range,” with the gross profit margin increasing by 8%-10%, and the material profit rate increasing by 50%, supporting rapid iteration.

(2) Environmental Benefits. LWRT production line’s single-piece energy consumption is reduced by 30% compared to PP-T20. Based on ISO 14067 measurement, the carbon footprint is reduced by 1.2 t; LWRT recycling rate is ≥95%, while that of traditional plastic is less than 15%. Through chemical decomposition technology, renewable materials can be obtained, with a renewable material proportion of ≥90%.

(3) Safety Benefits. In terms of high-temperature safety, the softening point of LWRT is >250°C, while that of PP-T20 is 158°C, which can effectively block thermal runaway of the battery and meets the GB 38031-2020 battery safety standard verification. In terms of crash safety, after lightweighting and stiffness optimization, during crash tests and simulation verification, its energy absorption efficiency increased by 25%, and the C-NCAP side impact dummy protection score improved by 0.8 points.

(4) Industry Promotion. The successful development of this model has driven the process of opening up the supply chain for LWRT in terms of process direction, driving the productivity of local Chinese suppliers by 200%, and reducing the tooling cost for the entire industry by 20%. The core concept of “cost reduction, efficiency increase, and greening” is perceived by the industry, which not only creates short-term profits for the enterprise but also promotes the high-quality and sustainable development of China’s auto industry. In the future, the environmental attributes of LWRT will be transformed into a key asset for international trade competition, becoming a key technological asset for the lightweighting competition of the global automotive industry.

3.2 Future Challenges

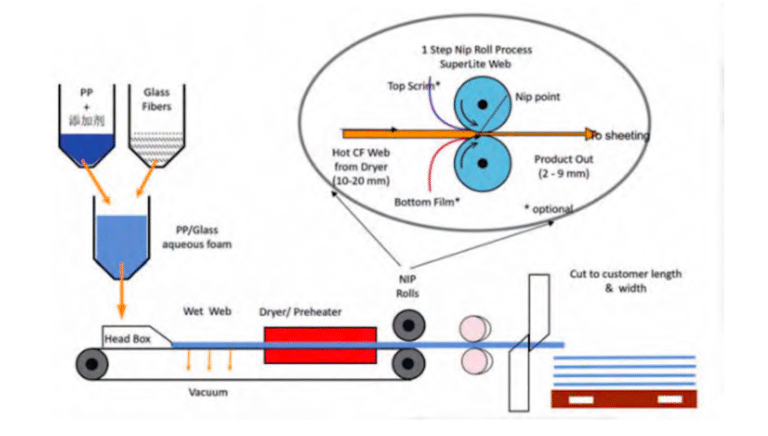

Although LWRT material has shown significant advantages, its industrial-scale promotion still faces multiple challenges. The production process of LWRT is complex, involving multiple stages such as fiber unwinding, netting, pre-compaction, and hot pressing, which require strict control of temperature and pressure gradients. Compared with the traditional injection molding process, its initial production yield rate was only 75%, and it needs to be increased to over 90% through the addition of equipment such as infrared thermal imaging monitoring. The core of raw material sources still relies on a few suppliers, and the domestic production rate of raw materials is only 60%, leading to high price fluctuation risks. Compared to a certain foreign vehicle model with a localization rate as high as 85%, we need to accelerate the progress of domestic substitution.

4 Conclusion

The engineering application of LWRT material in a certain vehicle model has proven that the lightweighting technology does not necessarily have to come at the cost of sacrificing performance or affordability. At the intersection of high-end technology sinking and universal demand upgrading, engineering innovation can be used to break market stereotypes. This type of technology, which balances weight reduction and cost reduction, is also a key leap for the Chinese auto industry from a “cost-performance advantage” to a “technology-driven rule output.”