Unveiling the “Electric Field Magician”: An In-Depth Analysis of Electrical Semiconductor Creped Paper

In modern power systems, the safe and efficient transmission of energy is paramount, from massive power plants right down to the outlets in our homes. Behind the scenes, an unsung hero makes this possible: insulation material. Today, we delve into a “smart” insulation material that plays a critical role in high-voltage electrical equipment: Electrical Semiconductor Creped Insulation Paper. It’s more than just an insulator; it’s like a magician that precisely controls electric fields to ensure the grid’s stability and safety.

Why Does High-Voltage Equipment Need “Smart” Insulation?

Imagine a high-pressure water pipe. If the pressure is too great, a weak point on the pipe wall could burst. The current in a high-voltage cable or transformer is like that high-pressure water, and the insulation is the pipe wall. Under ultra-high voltage, the electric field can become highly non-uniform, creating immense “electrical pressure” at certain points. If ordinary insulation is used, these pressure points will continuously stress and erode the material, leading to a destructive phenomenon known as “partial discharge.”

Partial Discharge (PD) is a tiny, localized electrical spark that occurs within or on the surface of an insulation material. While a single discharge is minuscule, frequent, long-term occurrences act like termites eating away at wood. They gradually break down the insulation’s molecular structure, eventually causing a complete insulation failure, which can lead to severe equipment faults and safety hazards.

Electrical semiconductor creped paper is the “smart protective suit” designed to solve this problem. It is neither a perfect insulator nor a perfect conductor but exists in a “semiconductive” state. This allows it to actively “guide” and “balance” the electric field, preventing dangerous concentrations of electrical pressure and thus suppressing the root cause of partial discharge.

The Professional Deep Dive: Core Technology of Semiconductor Creped Paper

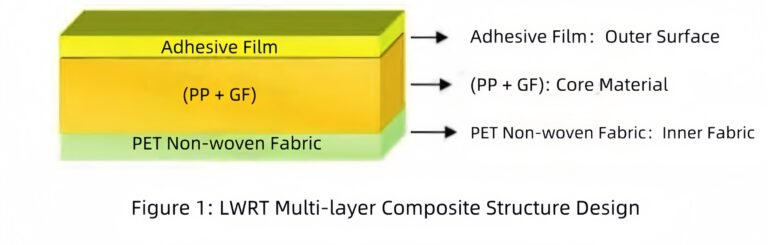

1. What Makes the Paper “Semiconductive”?

Its semiconductive property comes from uniformly adding materials like conductive carbon black to high-purity insulating paper pulp during the manufacturing process. This allows the paper’s surface resistivity to be precisely controlled (as shown in the table: ≥2400 OHM on the pros side, ≥2500 OHM on the cons side). This property enables it to block current flow while simultaneously allowing static charges to dissipate slowly and safely, thereby achieving a uniform electric field distribution.

2. The Ingenuity of the “Creped” Texture

The wrinkled, or “creped,” surface gives the paper excellent mechanical properties. As the table indicates, it boasts an Elongation at Rupture of ≥60%. This means it has outstanding flexibility and conformability when wrapping complex-shaped conductors or coils, resisting tearing and ensuring a tight, void-free fit.

| No. | Property | Unit | Requirements | |

| 1 | Nominal thickness | mm | 0.38 | 0.46 |

| 2 | Tolerance of thickness | mm | ±0.05 | ±0.05 |

| 3 | Quantify | g/m² | 110±10 | 130±20 |

| 4 | Elongation at rupture | % | ≥60 | |

| 5 | Tensile index | Nm/g | ≥50 | |

| 6 | Tensile strength | kN/m | 4.0 | 3.9 |

| 7 | Tear length | km | 3.6 | |

| 8 | Surface resistivity(pros) | OHM | ≥2400 | |

| 9 | Surface resistivity(cons) | OHM | ≥2500 | |

These strict parameters ensure the product’s long-term reliability in high-voltage operational environments.

Core Applications and Professional Advantages

Thanks to its superior performance, electrical semiconductor creped paper has become an indispensable material in both conventional and emerging power equipment.

Primary Application Scenarios:

- High-Voltage Instrument & Power Transformers: Used for lead wrapping and interlayer insulation foil winding to effectively shield static electricity and balance the internal electric field.

- Ultra-High Voltage (UHV) Power Cables: Serves as a shielding layer to protect the main insulation from partial discharge caused by non-smooth conductor surfaces or air gaps.

- Coil Insulation Wrapping for High-Voltage Electrical Equipment: Its excellent wettability allows it to bond well with insulating oils or resins, further enhancing overall insulation performance.

- New Energy Transformers: In wind and solar power systems, inverters generate fast-switching voltage pulses and unbalanced loads, placing higher demands on insulation. Semiconductor creped paper effectively manages these complex electric fields, safeguarding the stability of renewable energy systems.

Advantages Over Traditional Materials:

This material is designed to replace metallized paper and other surface-type semiconductor materials. Compared to metal foils (full conductors) or semiconductive tapes, it offers significant benefits:

- More Stable Performance: Its resistivity is stable, fundamentally solving issues like uneven coatings and flaking common in traditional coated semiconductor materials.

- Lighter Weight: Contributes to the lightweighting of equipment and reduces material costs.

- Superior Electric Field Balancing: More effectively resolves partial discharge issues, enhancing equipment reliability and operational lifespan.

Storage and Usage Specifications

Proper storage is crucial to maintaining product performance. The product should be stored in a dry, clean, and well-ventilated warehouse. It must be kept away from fire, heat sources, and direct sunlight. The standard storage period is 12 months. Products exceeding the storage period can still be used after passing a quality inspection.

Conclusion

As a high-performance specialty insulation material, electrical semiconductor creped paper is a cornerstone of safe and reliable high-voltage equipment operation, thanks to its exceptional ability to balance electric fields, shield static electricity, and suppress partial discharge. With the global energy transition towards renewables, its application in cutting-edge fields like new energy transformers and smart grids will only grow, providing a solid material foundation for building a stronger, more stable power grid for the future.

Electrical Semiconductor creped insulation paper is a new kind of special shielding material. Mainly used for high voltage transformer, new energy transformer lead wrapping, interlayer insulation foil winding, ultra high voltage power cable, high voltage electrical equipment lead and coil insulation wrapping. It can replace metallized paper and other surface type semiconductor materials. It has excellent wettability, low conductivity, shielding static electricity, also can solving partial discharge and balancing high voltage electric field.

◎ Recommended width:

700mm, 1100mm; it can also slit it to be belts. Tailor-made by customers’ requirements is available.

◎ Storage

The product should be stored in dry, clean and well-ventilated warehouse. The fire, heat sources and direct sunshine should be avoided. The storage period is one year, qualified products exceeding the storage period can still be used.

-3-768x491.jpg)